In this post I am going to put an all in one place what your need to do in order to calibrate your 3D. Yes, I do know that there is a bunch of articles out there telling you how to do it but there is not really an all in one, in plain English version.

Checking your filament size

We all know that this is a little basic for experience/novice users. But it does play an important role in the quality of your prints. Just because you purchase a roll of filament does not mean it is absolutely 1.75 mm. I believe that manufacturers try to reach the industry standard but due to machine tolerances, environmental conditions, and speed of production its difficult to make everything perfect.

Measure your filament (need calipers set in millimeters)

- Before you load up your filament to your printer you are going to want to roll out about 1m/3ft of filament still attached to the roll.

- Take multiple measurements throughout the 1m/3ft section and write them down. You might want to do 6+ locations

- Add up all the measurements that you wrote down

- Divide by number of measurements you took to get your average

IE: (Measurement + measurement) / Amount of measurements

Now you are going to want to take your average measurement that you took and enter this into your slicer.

- For Cura you need to open up the machine settings that you have active, click on your extruder, and put your number on “Compatible material diameter”

- For s3d open up your process, go to the tabs named other, and input your number in “Filament diameter”

Extruder Calibration

For those who are new to 3D Printing your extruder is the place where the filament gets fed into your machine. It is typically has a motor and some type of gear to grab onto the filament and feed it. There is a quite a bit of options for your extruder but in the end it still functions the same.

For Bowden Setups (need calipers or measuring ruler with millimeters)

Bowde set ups are the most typical way to feed a printer non-flexible filament. It is not only cheaper but typically the better weight option for print carriages.

- Take your bowden tube out of the hot end section. Leave the tube in the extruder

- Feed filament so it is sticking slightly out of the end of the tube

- Cut flush to the tube

- Tell your printer to feed/extrude 100mm of filament. Cut flush and repeat for about 2 more times. You want about 3 or more to get an average.

- There is a few ways to do this. Please consult your printer manual to find out how

- Please also note that you only need to tell it to extrude 100mm. If it is not near or it’s above that dont worry we will fix that

- Once you have about 3 lengths of filament you might need to gently work the filament to be as straight as you can get it. try not to break it or you will need to extrude more

- Use the math down below

For Direct Drive

- Measure from the

Math

Get average (in my case 105.6)

Get current firmware (e)steps (typically 100)

Firmware steps x 100 = 10000

10000 / average (105.6) = 94.69

Change your firmware steps to be the number you got in my case 94.69. upload firmware and test/repeat until happy.

For marlin you need to look for the below in Configuration.h file and change the last value to your new esteps. Note that the first 3 values will be set in your firmware already.

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 800, 94.69}

Once you are done calibrating make sure you add the tube in the hot end section and make sure it is pushed all the way back down or you will have issues with clogs

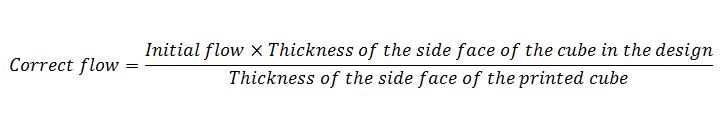

Calibrate Flow

TBD